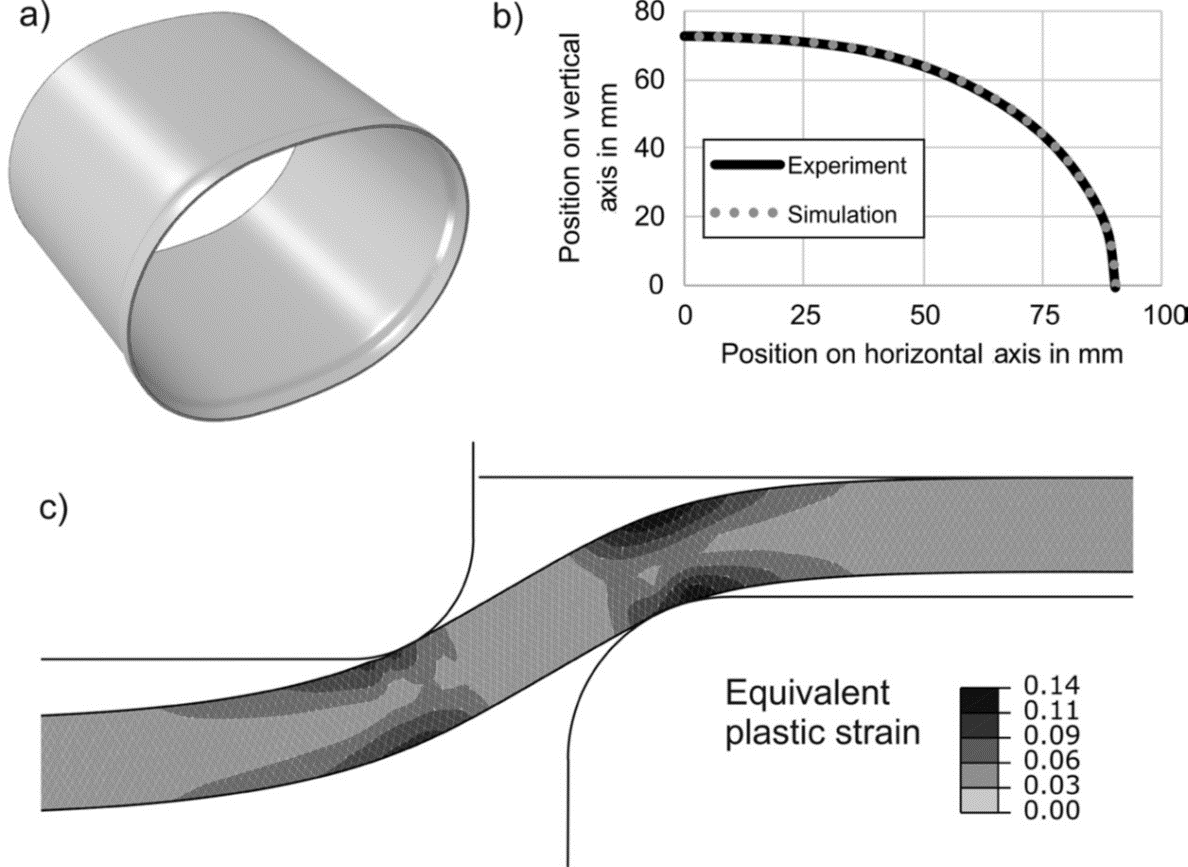

Shape prediction and improvement for expansion of non-round tubes

Increasing requirements on the utilization of assembly space result in more complex tube cross sections of containers. Consequently, fulfilling the tight shape tolerances becomes more challenging. Therefore, the technical design of the process must be improved to avoid an increase of iteration loops inmanufacturing. For non-round tube cross sections there are no analytical models available. Thus, a numerical Finite-Element model is created. The model will help to analyze the mutual influence of springback after expansion and shape deviations by shape dependent pressure on the inside. Initially, the expansion of the tube at the free end is investigated (see figure a). The corresponding numerical model already predicts the shape in excellent agreement with the real tube (see figure b). Furthermore, the analysis revealed information otherwise not available, such as the plastic strain occurring in the process (see figure c), which helps to improve process understanding.