Improvement of Product Properties by Selective Induction of Residual Stresses in SPIF Properties by Selective Induction of Residual Stresses in SPIF

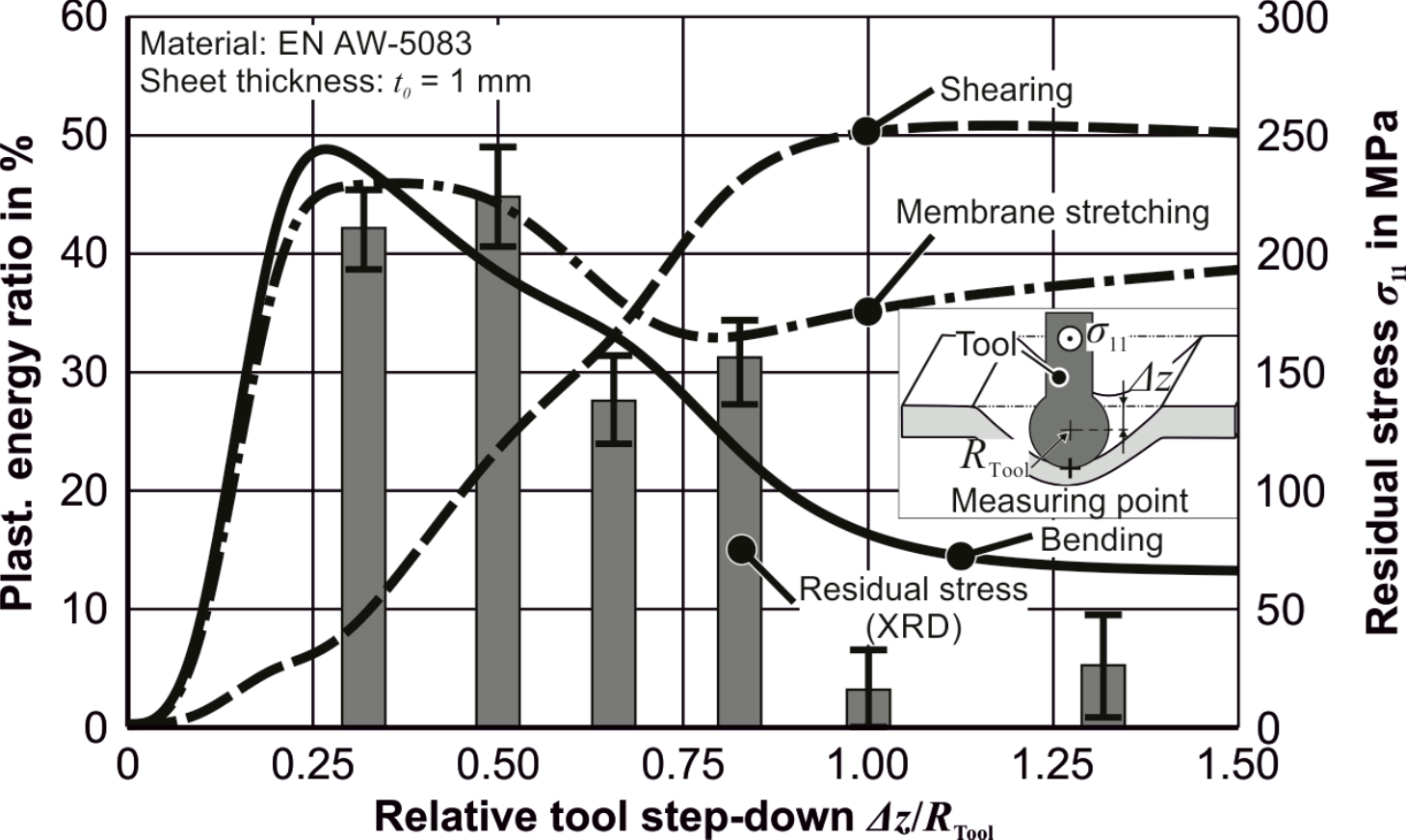

Within the scope of the project cooperation with the Institute for Materials Science and Technology (Metallic Materials) of TU Berlin the relationship between the forming mechanisms shearing, bending, normal loading, and hydrostatic compression in Single Point Incremental Forming (SPIF) and the resulting residual stress state is analyzed. The aim of this research project is to improve the operational behavior of incrementally formed components by deliberately adjusting the residual stress state during the forming process. The residual stresses are induced locally and defined by adjusting the parameters of the incremental sheet metal forming process. The adjustment of the relative tool step-down (quotient of tool step-down Δz and tool radius RTool) influences the plastic energy fraction of each forming mechanism. This is correlated with the resulting residual stress state. It was found that particularly the bending mechanism intensifies tensile residual stresses on the tool-side.

Within the scope of the project cooperation with the Institute for Materials Science and Technology (Metallic Materials) of TU Berlin the relationship between the forming mechanisms shearing, bending, normal loading, and hydrostatic compression in Single Point Incremental Forming (SPIF) and the resulting residual stress state is analyzed. The aim of this research project is to improve the operational behavior of incrementally formed components by deliberately adjusting the residual stress state during the forming process. The residual stresses are induced locally and defined by adjusting the parameters of the incremental sheet metal forming process. The adjustment of the relative tool step-down (quotient of tool step-down Δz and tool radius RTool) influences the plastic energy fraction of each forming mechanism. This is correlated with the resulting residual stress state. It was found that particularly the bending mechanism intensifies tensile residual stresses on the tool-side.