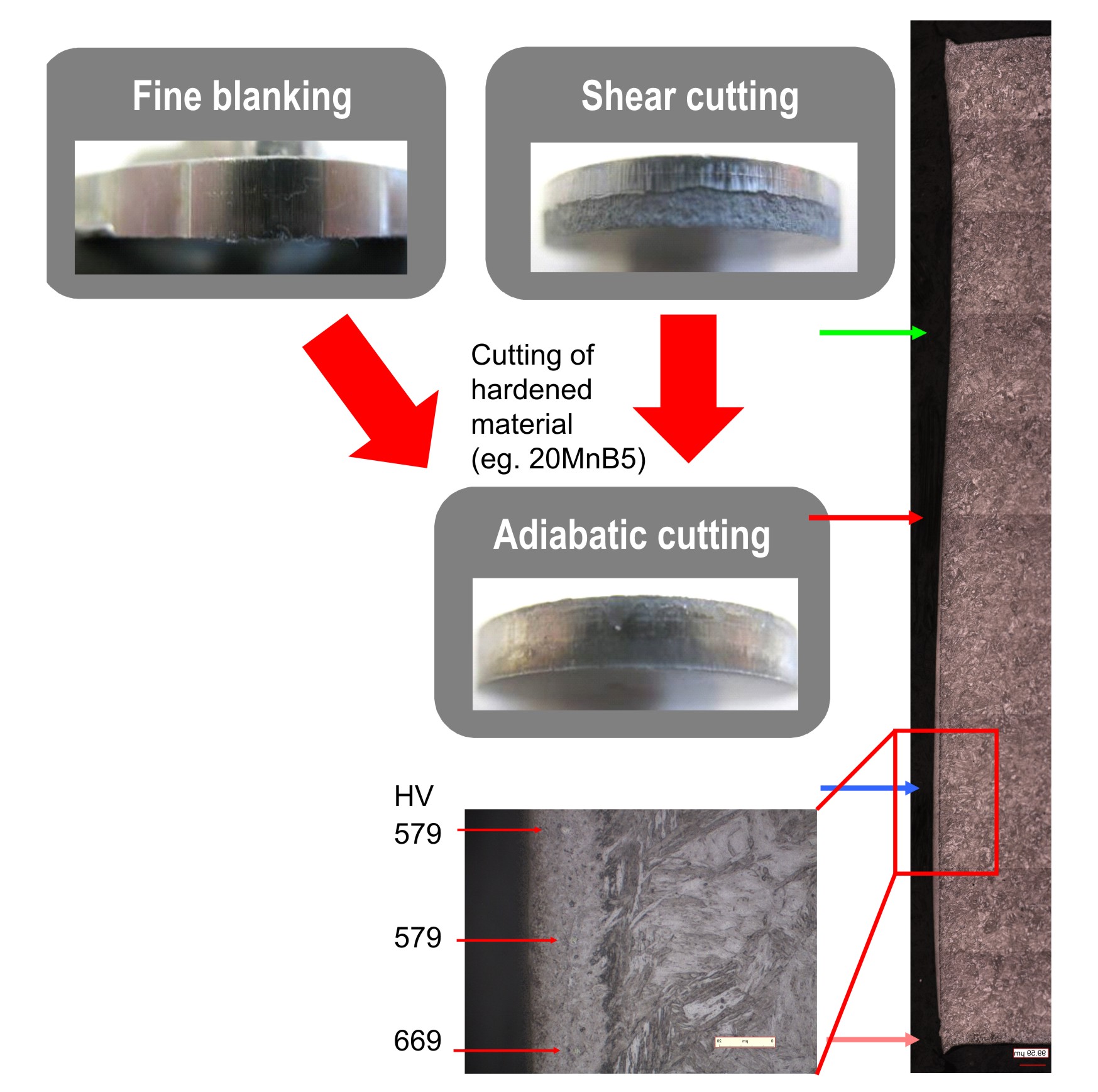

Simulation strategies for the application of adiabatic cutting in sheet metal part manufacturing in the context of material scienceThe quality of the cutting edge of sheet metal parts manufactured by adiabatic cutting processes is excellent. Moreover, adiabatic cutting processes have a great potential for the processing of advanced high strength steels (AHSS). A fundamental understanding of the process and the availability of efficient simulation strategies are necessary requirements to establish the technology for the industrial cutting of sheet material. The aim of this project is the creation of a simulation tool which considers the relevant technological and microstructural processes. The simulation tool is validated by the results of material characterization experiments which analyze the temperature-dependent and strain-rate dependent behavior. The thermo-mechanical behavior is considered by material models for ductile damage in numerical simulations. Demonstrator parts are manufactured on adiabatic punching presses for additional validation of the simulation tool.

|

Project duration:01.11.2015 - 30.04.2018

Researcher:Mr. M.Sc. Fabian Schmitz |